In-Feed Grinding

This is the preferred method when parts have shoulders, heads or irregular shapes and projections that makes thru-feed grinding impossible.

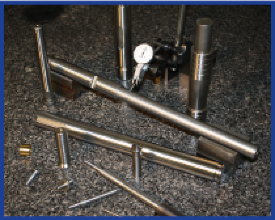

In-feed grinding differs from through-feed grinding in that the part is not fed axially so that the ground surface does not need to be a circular cylinder. The grinding wheel can be dressed to accommodate the part. Once the work piece part is in place, the grinding wheel is fed in radially.In-feed grinding is illustrated right.

In-feed grinding differs from through-feed grinding in that the part is not fed axially so that the ground surface does not need to be a circular cylinder. The grinding wheel can be dressed to accommodate the part. Once the work piece part is in place, the grinding wheel is fed in radially.In-feed grinding is illustrated right.

Because of the set up time involved for each part, in-feed grinding does not have the high throughput of thru-feed grinding.

This is the preferred method when parts have shoulders, heads or irregular shapes and projections that makes thru-feed grinding impossible.

In-feed grinding differs from through-feed grinding in that the part is not fed axially so that the ground surface does not need to be a circular cylinder. The grinding wheel can be dressed to accommodate the part. Once the work piece part is in place, the grinding wheel is fed in radially.In-feed grinding is illustrated right.

In-feed grinding differs from through-feed grinding in that the part is not fed axially so that the ground surface does not need to be a circular cylinder. The grinding wheel can be dressed to accommodate the part. Once the work piece part is in place, the grinding wheel is fed in radially.In-feed grinding is illustrated right. Because of the set up time involved for each part, in-feed grinding does not have the high throughput of thru-feed grinding.

![[IMAGE]](images/122_preferred_centerless_inc_logo.png)