Thru-Feed Grinding

The most common type used to grind straight, cylindrical parts that have no heads or other projecting part up to 6.5 inch diameter or 12 feet long.

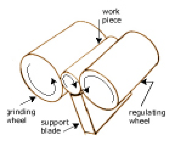

In thru-feed grinding, the part rotates between the grinding wheel and a regulating wheel as shown right.

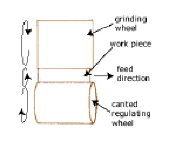

For through-feed grinding, one or both wheels of the centerless grinding machine are canted out of the horizontal plane, as shown below. This imparts a horizontal velocity component to the work piece, so that outside feed mechanisms are not necessary.

The grinding wheel is canted with respect to the other two axes so that a component of its surface velocity pushes the part in the direction shown. This auto feeding characteristic is useful for rapidly processing many parts in quick sequence. Because of the axial movement, through-feed parts can only have right circular cylindrical ground surfaces. The wheel cannot be dressed to grind more complex shapes. Thru-feed grinding is primarily a mass-production process because of its high throughput.

The grinding wheel is canted with respect to the other two axes so that a component of its surface velocity pushes the part in the direction shown. This auto feeding characteristic is useful for rapidly processing many parts in quick sequence. Because of the axial movement, through-feed parts can only have right circular cylindrical ground surfaces. The wheel cannot be dressed to grind more complex shapes. Thru-feed grinding is primarily a mass-production process because of its high throughput.

The most common type used to grind straight, cylindrical parts that have no heads or other projecting part up to 6.5 inch diameter or 12 feet long.

In thru-feed grinding, the part rotates between the grinding wheel and a regulating wheel as shown right.

For through-feed grinding, one or both wheels of the centerless grinding machine are canted out of the horizontal plane, as shown below. This imparts a horizontal velocity component to the work piece, so that outside feed mechanisms are not necessary.

The grinding wheel is canted with respect to the other two axes so that a component of its surface velocity pushes the part in the direction shown. This auto feeding characteristic is useful for rapidly processing many parts in quick sequence. Because of the axial movement, through-feed parts can only have right circular cylindrical ground surfaces. The wheel cannot be dressed to grind more complex shapes. Thru-feed grinding is primarily a mass-production process because of its high throughput.

The grinding wheel is canted with respect to the other two axes so that a component of its surface velocity pushes the part in the direction shown. This auto feeding characteristic is useful for rapidly processing many parts in quick sequence. Because of the axial movement, through-feed parts can only have right circular cylindrical ground surfaces. The wheel cannot be dressed to grind more complex shapes. Thru-feed grinding is primarily a mass-production process because of its high throughput.

![[IMAGE]](images/122_preferred_centerless_inc_logo.png)